Welcome to the Advanced Product Development Resource Center

Engineering Resource Center News

Engineering Resource Center Resources

Latest News

Produced in partnership with Dell and NVIDIA, the Advanced Product Development Resource Center is an ever-growing repository of information to help design engineering teams capitalize on digital disruption through the use of today’s most advanced computing, design, simulation and visualization technologies.

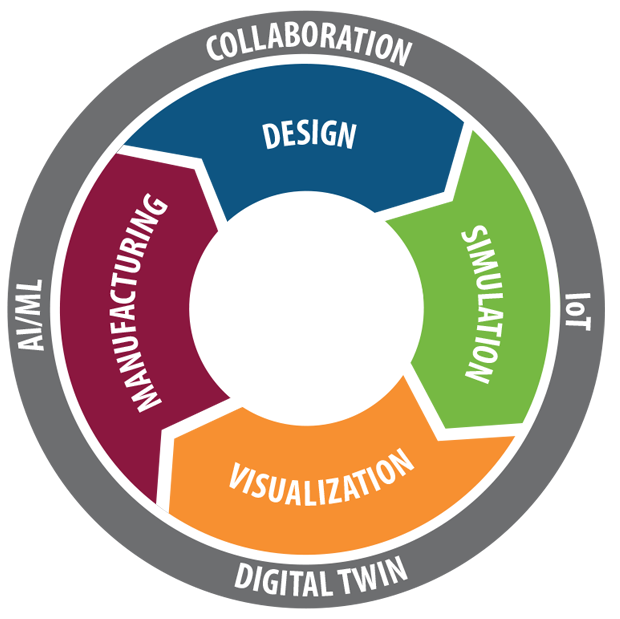

Our coverage of immersive design (VR/AR, real-time rendering, real-time simulation, photorealistic material rendering, toolpath simulation), design complexity (larger models, system design, multiphysics, cyber-physical systems), mobility (mobile workstations, cloud computing, virtual machines), digital disruption (big data/IoT; digital twins; AI/machine learning; automation/smart factories), collaboration (connectivity, 5G, data exchange, VR, PLM), and increased productivity (VAR certification, workstation configuration, GPU accelerated computing) is divided among five stages of the product development cycle.

Conceptual Design

Even the napkin sketch to get initial ideas onto paper has gone digital. Designers and engineers can sketch out concepts for form, fit, function and interactivity on the screen. Digitization means those concepts can be easily stored for future use so no idea is lost, quickly shared with collaborators and, when the time is right, exported into CAD. Conceptual design software has advanced to the point where generative design algorithms can recommend designs they may never have considered.

Detailed Design

Traditional computer-aided design (CAD) software has taken advantage of ever-increasing computing power to enable globally dispersed design engineering teams to work with larger, more complex components that comprise the interconnected mechanical, electrical and software systems of today's products. As CAD programs have expanded to include useful initial simulation functionality, data visualization, data management, rendering features and more, workstations, servers, clusters and cloud-computing advances ensure design engineers can innovate at the speed of thought.

Simulation & Analysis

The lines separating CAD and computer-aided engineering (CAE) simulation & analysis software continue to blur, but experts employing numerical engineering simulation techniques such as structural finite element analysis (FEA), computational fluid dynamics (CFD) and multibody simulation save significant time and money that would otherwise be spent on physical testing, engineering change orders from manufacturing and even product recalls. Predictive engineering technologies driven by advances in computing and graphics are allowing engineers to optimize product design spaces to meet specific requirements, which enables true simulation-led design.

Visualization

Simulation can predict how a product will perform under various conditions, but in today's experience economy, the way a product looks, feels and interacts with users is just as important. Visualization software uses powerful graphics processing advances to create photorealistic renderings of the product, including the varied materials inherent in products and how they react to different real-world lighting conditions. Visualization also improves collaboration by showing stakeholders how a product will look and perform—even to the point of allowing users to experience the product in virtual reality (VR) and augmented reality (AR). Today's virtual prototypes have become so realistic that products can be marketed before they're even physically produced.

Computer-Aided Manufacturing (CAM)

Advances in 3D printing/additive manufacturing and computer-aided manufacturing are having a significant impact on the design cycle. Design engineers use hardware and software that can simulate CAM toolpaths and ease design for additive manufacturing (DFaM) learning curves to create functional prototypes and short-run products to help avoid any design issues that could bottleneck the manufacturing process.

Plus +

The design cycle is not a simple circle. It consists of a multitude of data points flowing in many different directions along the product lifecycle that prompt decisions to be made and actions to be taken in parallel. Connected products that make up the digital disruption driving businesses today—the internet of things (IoT), the industrial IoT, autonomous cars, digital twins and the factory of the future—all start with design engineering, but design engineering doesn't end at manufacturing. Those connected products are collecting big data about how and where they are used that can be parsed using artificial intelligence (AI) to help design engineers develop the next generation of improved products.

The Advanced Product Development Resource Center's mission is to help design engineers capitalize on the amazing technological advances in product design that are driving digital disruption in manufacturing. Visit the resource center for the latest developments on technological advances, videos, white papers and more from DE, Dell and NVIDIA.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

DE’s editors contribute news and new product announcements to Digital Engineering.

Press releases may be sent to them via DE-Editors@digitaleng.news.