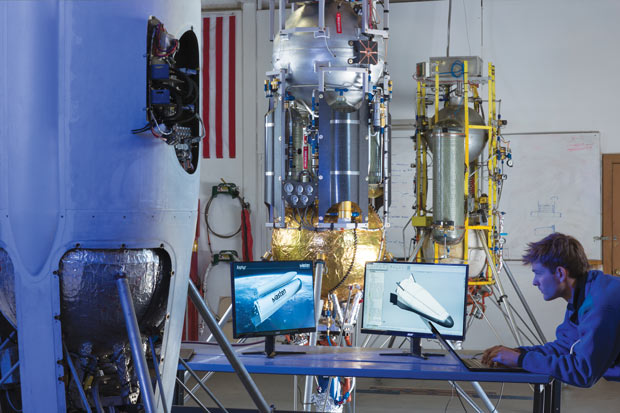

Current and future Masten Space Systems rockets, with Masten engineer Kyle Nyberg. Image courtesy of Chad Slattery.

January 1, 2016

Current and future Masten Space Systems rockets, with Masten engineer Kyle Nyberg. Image courtesy of Chad Slattery.

Current and future Masten Space Systems rockets, with Masten engineer Kyle Nyberg. Image courtesy of Chad Slattery.When Dave Masten traded the life of a Silicon Valley coder for that of a self-taught rocketeer in Mojave, CA, he didn’t start with much. But, with three other renegades and a portable test stand towed by a pickup, he set up shop in a World War II-era hangar at the Mojave Airport, building rocket engines and vertical takeoff/vertical landing vehicles to go with them.

Eleven years later, the company that bears Masten’s name has a solid business testing hardware and software designed for planetary landers. Low and slow is the name of the game here, as customers including NASA and Draper Laboratories use Masten Space Systems rockets as testbeds for their own technologies designed to help rocket-powered landers touch down safely on airless worlds like the moon or in the rarified atmosphere of Mars.

While those testbed vehicles have been the company’s bread and butter for more than a decade, Masten’s vision has always been to reach space from Earth. And to do that, it will have to build rockets that go faster. Much faster. Fast enough, in fact, to require Masten engineers to spend significant resources on calculating the effects of aerodynamic forces on their designs or see them disintegrate in the more-than-gale-force winds of hypersonic flight.

Now, with a new contract in hand from the Defense Advanced Research Projects Agency (DARPA), they are finally getting the chance to do so.

A Boost from DARPA

“Aero is a factor and we have to account for it, but it’s not been the primary research or testing goal,” says Sean Mahoney, who now runs the company that Dave Masten founded. (Masten now serves as CTO of the company.)

What the company has lacked in aerodynamics expertise, it has more than made up for in experience building reusable rockets that can fly frequently and affordably—just the qualities DARPA program manager Jess Sponable wanted for his XS-1 program.

In June 2014, Masten Space Systems won a $2.99 million contract from DARPA to design an experimental spaceplane, to be called the XS-1. Aerospace giants Boeing and Northrop Grumman were also funded to create competing designs.

The XS-1 program, run by Sponable, seeks to foster the creation of an unmanned launcher the size of a business jet that can hit 10 times the speed of sound and reach the edge of the atmosphere. From there, the XS-1 will launch an upper stage capable of sending a 3,000- to 5,000-lb. payload into low Earth orbit. The XS-1 envisioned by Sponable should be able to launch 10 times in as many days and cost no more than $5 million for each satellite launch. That dollar amount isn’t arbitrary; it’s about one-tenth the cost of current launch systems.

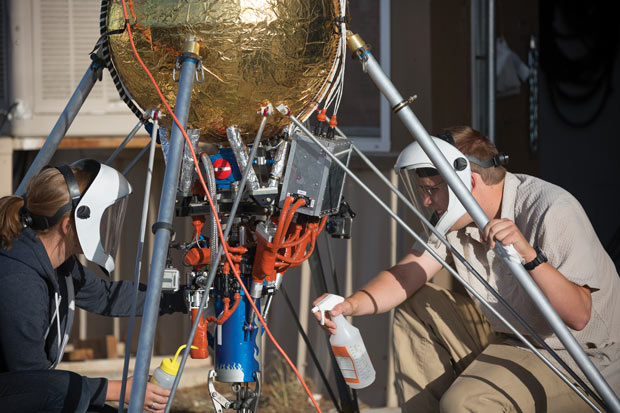

Masten rocketeers Ellen Moyer and Wyatt Rehder prep Masten’s Xodiac rocket for flight. Image courtesy of Chad Slattery.

Masten rocketeers Ellen Moyer and Wyatt Rehder prep Masten’s Xodiac rocket for flight. Image courtesy of Chad Slattery.Hypersonic speed isn’t a necessity for vehicles that serve as the first stage of a satellite launcher. Instead, the requirement that the XS-1 achieves Mach 10 flight is designed to enable further research into—as the DARPA solicitation put it—both “next-generation space launch and global reach aircraft.” It also significantly increases the aerodynamic challenges that must be solved in designing the craft.

To help solve those challenges, Masten brought in aerodynamicist Allan Grosvenor to serve as senior engineer and aerodynamics lead. It’s his job to manage the effort to enable the Masten XS-1 design to survive atmospheric flight at Mach 10.

Simulating Hypersonic Flight

Overseen by Dennis Poulos, program manager for the XS-1 program at Masten, the engineering team builds individual components of the design using SOLIDWORKS. Grosvenor pulls what he needs from there to do the computational fluid dynamics (CFD) analysis needed to simulate the aerodynamic forces that will be experienced by the vehicle after it is built.

“I get the vehicle outer mold line (OML) along with the aerodynamic control surfaces, and then I put that into the CFD-related codes that I’m using,” says Grosvenor. “I’m able to actually reverse-engineer that OML into a parametric model, which is important for vehicle design studies focused on evolving aerodynamic performance and controllability.”

For example: “We’re using CFD to generate aerodynamic forces and moments that are then used for evaluating performance and controllability. We’re also generating loads and heating maps all over the vehicle as well as hinge moments on the aerodynamic surfaces,” says Grosvenor.

To get the data, Grosvenor logs onto supercomputers at the Department of Defense High-Performance Computing Centers via his MacBook Pro laptop. “I can’t say enough about what an enabler having access to those systems is for a small company trying to do this kind of project,” said Grosvenor. “If we did not have the ability to run these kinds of jobs on these kinds of systems, it would radically change what would be feasible for us to contemplate and the way we go about doing it.”

Although Grosvenor has to share time on the supercomputers with other users, he says the power available to him lets him get far more analysis done in much less time than would be possible otherwise. A typical job might run overnight, giving him calculations on aerodynamic loads and heating from air friction for every 20 seconds of a simulated XS-1 flight for a variety of design iterations.

Grosvenor accesses several supercomputers. They include a Cray XE6 known as Garnet, a Cray XC40 known as Excalibur and a Cray XC30 called Lightning. He also uses an SGI ICE X called Spirit. CFD tools provided by NUMECA running on Linux crunch the numbers.

Once he has the data back from the supercomputers, Grosvenor feeds it to team members working on the affected portions of the vehicle design in progress, which allows them to adjust their own work for maximum performance of the vehicle.

Looking to the Future

The entire Masten team now numbers 30 people, and the company is actively growing. Ramping up for the XS-1 program, says Mahoney, has people “stacked on top of each other” in their current space. “We’ll be adding some more physical space soon.”

Masten’s work on the XS-1 design will soon move to wind tunnel testing of scale models at a facility that has yet to be determined. Soon afterward, in mid-2016, the Phase 1 portion of DARPA’s XS-1 program for which Masten was awarded its contract will conclude. And Masten Space Systems will pull hard to land the XS-1 Phase 2 contract.

For Phase 2, DARPA will select only one contractor to actually build the XS-1. After Masten and its competitors submit their applications, DARPA expects to make the decision on who will build the vehicle by September of 2016.

If all goes well, in 2019 the XS-1 will undergo flight testing for Phase 3 of the program, during which it will have to demonstrate all of the capabilities requested by DARPA, including flying 10 times in 10 days and launching a satellite. DARPA has made available a total of $140 million for Phases 2 and 3.

Once the vehicle design has been validated through flight tests, DARPA will hand off the project, along with the building of operational vehicles to other organizations, just it has done for countless other projects throughout the agency’s more-than-50-year history.

In the meantime, Masten Space Systems continues its work with the landers that put it on the aerospace testing map.

On a recent fall afternoon, the Masten team prepped its Xodiac lander for a test flight in support of internal research and development in advance of flying the vehicle for a customer. “We’re out there on a very frequent basis,” says Mahoney. That rocket and the two others the company routinely flies still fit on trailers, just as Masten rockets have done since Dave Masten founded the company in 2004.

It’s all part of a design philosophy that calls for frequent flights and rapid turnaround times for each vehicle; a philosophy that may soon get Masten Space Systems into orbit.

More Info:

Subscribe to our FREE magazine, FREE email newsletters or both!

About the Author

Michael Belfiore’s book The Department of Mad Scientists is the first to go behind the scenes at DARPA, the government agency that gave us the Internet. He writes about disruptive innovation for a variety of publications. Reach him via michaelbelfiore.com.

Follow DE