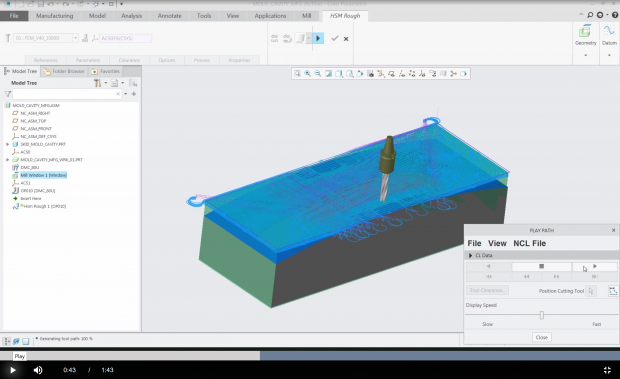

PTC has released version 5.0 of its Creo design from concept to manufacturing system. One of its key enhancements is a new Mold Machining extension that provides high-speed machining toolpaths optimized for molds, dies, electrodes and prototype machining. Image courtesy of PTC.

Latest News

April 4, 2018

PTC has announced Creo 5.0, the latest release of its design concept to manufacturing design environment. With Creo 5.0, PTC says, concepts can be transformed into smart, connected products, bridging the physical and digital worlds with augmented reality (AR) capabilities in every seat.

Creo 5.0 introduces five new and extended capabilities for product design, including two new extensions for additive and subtractive manufacturing, an extension for computational fluid dynamics (CFD) flow analyses, an extension for computer-aided manufacturing (CAM) and topology optimization. Additionally, version 5.0 presents a variety of productivity enhancements.

Creo 5.0 introduces a Mold Machining Extension. This new capability provides high-speed machining toolpaths optimized for molds, dies, electrodes and prototype machining. Image courtesy of PTC.

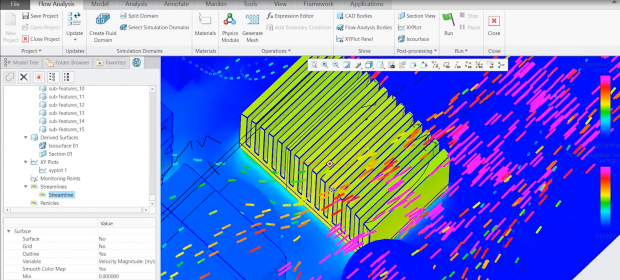

Creo 5.0 introduces a Mold Machining Extension. This new capability provides high-speed machining toolpaths optimized for molds, dies, electrodes and prototype machining. Image courtesy of PTC.The Creo Flow Analysis CFD extension allows designers, engineers and analysts to simulate such issues as liquid and gas fluid flows directly within Creo. PTC says that the Creo workflow between CAD design and CFD allows users to integrate analysis early and often. The extension is directly integrated within Creo, is easy to use and has been purpose-built specifically for the design engineer, according to PTC. Premium capabilities are available for analysts.

The new Creo Mold Machining extension provides high-speed machining capabilities that are optimized for molds, dies, electrodes and prototype machining, reports PTC. Creo 5.0 supports three-axis and 3+2 positioning machining, the company adds.

A new Flow Analysis extension for use with Creo 5.0 offers designers the tools to execute CFD-based analyses of liquids and gases early and often during the design process. Image courtesy of PTC.

A new Flow Analysis extension for use with Creo 5.0 offers designers the tools to execute CFD-based analyses of liquids and gases early and often during the design process. Image courtesy of PTC.For additive manufacturing, Creo enables users to design, optimize, print check and then fabricate 3D parts without multiple pieces of software. Version 5.0 introduces the Creo Additive Manufacturing Plus Extension for Materialise, which extends these capabilities to metal parts, allowing users to print production-grade parts directly from Creo. Additionally, the extension allows users to connect with the Materialise online library of print drivers and profiles.

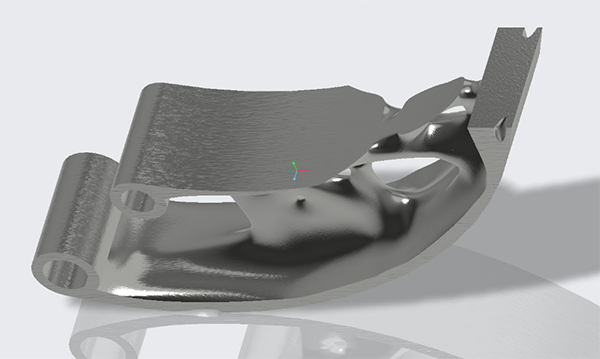

Creo 5.0’s new Creo Topology Optimization Extension is said to automatically create optimized designs based on a defined set of objectives and constraints. This, PTC explains, enables users to create optimized and efficient parts. The Creo Topology Optimization Extension will be available as part of the first maintenance build of Creo 5.0, which is scheduled for release this summer, according to PTC.

PTC says that, after users define objectives and constraints, Creo’s new Topology Optimization capability will create optimized, parametric geometry. This new extension will be available in the summer 2018 maintenance build of Creo 5.0. Image courtesy of PTC.

PTC says that, after users define objectives and constraints, Creo’s new Topology Optimization capability will create optimized, parametric geometry. This new extension will be available in the summer 2018 maintenance build of Creo 5.0. Image courtesy of PTC.A variety of productivity improvements for product design make their debut in Creo 5.0. Key enhancements cited by the company include an improved user interface, geometry creation with sketch regions and volume helical sweeps. Creo 5.0 also introduces improvements to surfacing, sheet metal design and the application of draft features involving rounds.

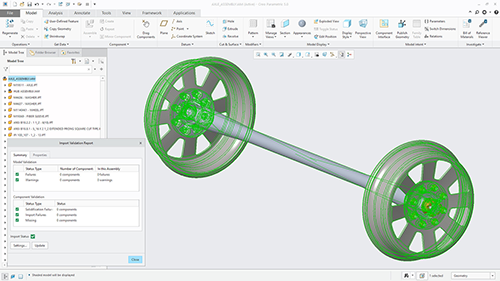

Beginning with version 5.0, Creo users can also now design in Creo while maintaining the perspective display mode. Additionally, the Creo Collaboration Extension for Autodesk Inventor now supports bidirectional exchange of both parts and assemblies with Autodesk Inventor and Creo Parametric. New capabilities in Creo 5.0 allow creators to manage access to the AR experiences they’ve created.

Beginning with Creo 5.0, the Creo Collaboration Extension for Autodesk Inventor now supports the bidirectional exchange of both parts and assemblies. Image courtesy of PTC.

Beginning with Creo 5.0, the Creo Collaboration Extension for Autodesk Inventor now supports the bidirectional exchange of both parts and assemblies. Image courtesy of PTC.“Product design is fundamentally changing, and Creo continues to evolve to meet the needs of our customers. With Creo, companies can go from the earliest phases of design to a smart, connected product,” said Brian Thompson, senior vice president, CAD Segment, PTC, in the Creo 5.0 announcement. “Improved functionality and new capabilities, like additive manufacturing, set Creo apart, and give companies a true competitive edge all the way from concept to manufacturing.”

For more information on what’s new in PTC Creo 5.0, go here.

Watch an overview of PTC Creo 5.0.

See how Creo 5.0’s Flow Analysis extension works.

Download the Creo for CAM and additive manufacturing data sheet.

Download a 30-day trial of Creo 5.0.

Download details on Creo 5.0’s productivity enhancements.

See why DE’s editors selected PTC Creo 5.0 as their Pick of the Week.

Sources: Press materials received from the company and additional information gleaned from the company’s website.

Subscribe to our FREE magazine, FREE email newsletters or both!

Latest News

About the Author

Anthony J. Lockwood is Digital Engineering’s founding editor. He is now retired. Contact him via de-editors@digitaleng.news.

Follow DE